Commercial elevator downtime costs the average building $2,500 per hour in lost productivity and tenant satisfaction. With modern monitoring technology, property managers can now prevent 85% of elevator failures before they occur. Here are the five essential monitoring tools that are transforming commercial elevator management in 2026.

1. Remote Monitoring Systems with Real-Time Analytics

Remote monitoring platforms have become the backbone of proactive elevator maintenance. These systems track performance metrics 24/7 and instantly alert facility teams when anomalies occur.

Key Features:

- Real-time performance tracking across all elevator systems

- Automatic fault detection and immediate notifications

- Historical data analysis for usage pattern identification

- Integration with building management systems (BMS)

Why It Matters:

Remote monitoring reduces emergency service calls by 60% and extends elevator lifespan by identifying wear patterns before they cause failures. The BBX VISIBLE IoT Platform exemplifies this technology, offering comprehensive oversight for high-rise buildings with detailed dashboard analytics.

Implementation Benefits:

- Immediate notification of mechanical faults

- Reduced response times from hours to minutes

- Predictive insights that prevent costly breakdowns

- Detailed reporting for maintenance planning and budgeting

Property managers using remote monitoring report average maintenance cost reductions of 25-35% within the first year of implementation.

2. AI-Driven Predictive Maintenance Systems

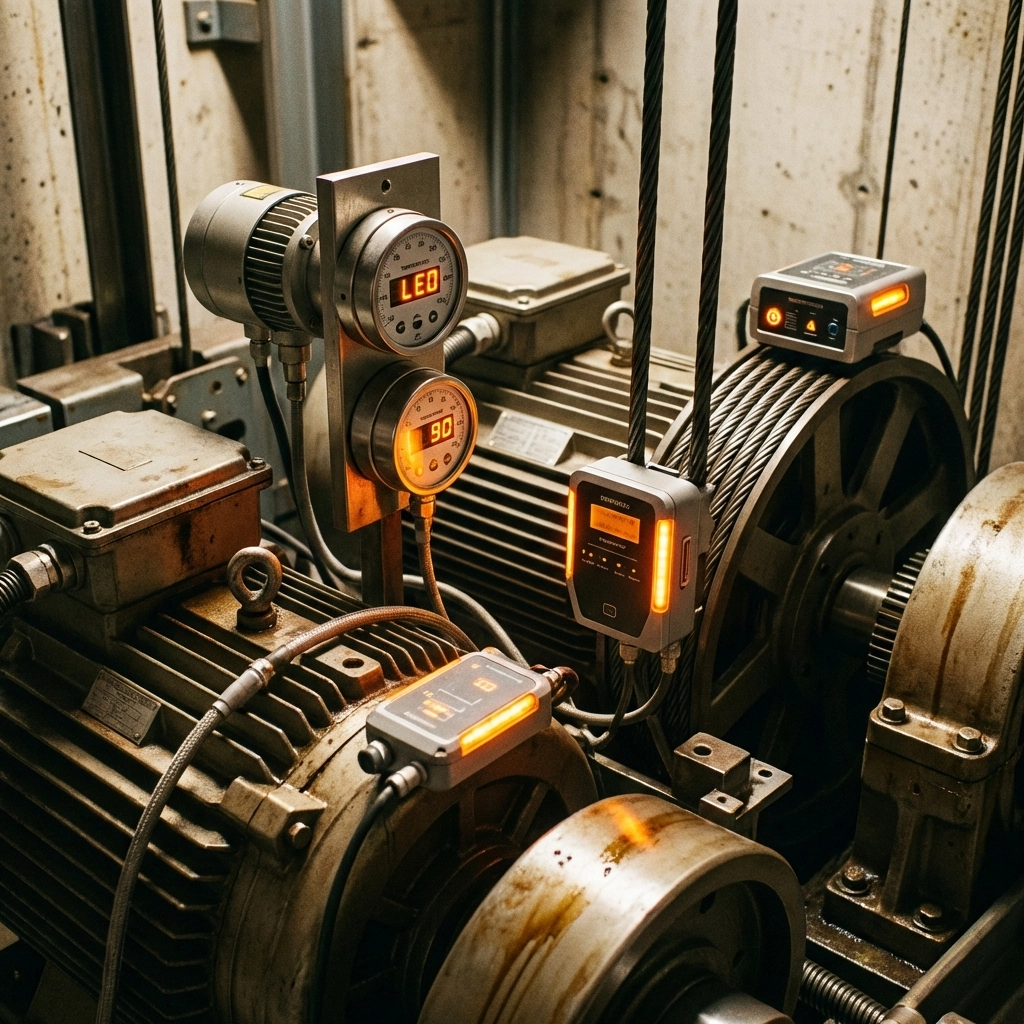

Artificial intelligence has revolutionized how we approach elevator maintenance. Advanced sensor networks collect data on motor temperatures, door operations, vibration patterns, and cable tension, feeding this information into AI algorithms that predict failures weeks in advance.

Core Capabilities:

- Motor temperature and performance analysis

- Door operation cycle monitoring

- Vibration pattern recognition

- Cable wear and tension assessment

- Digital twin simulation for scenario planning

Proven Results:

AI-driven systems are reducing elevator downtime by more than 30% across commercial installations globally. These platforms use machine learning to continuously improve their predictive accuracy, becoming more effective over time.

Strategic Advantages:

- Schedule maintenance during off-peak hours

- Order replacement parts before failures occur

- Eliminate surprise breakdowns during critical business periods

- Optimize technician schedules and resource allocation

The technology pays for itself through reduced emergency calls and extended component life, typically showing ROI within 18 months.

3. Smart Sensor Networks for Comprehensive Diagnostics

Modern elevator monitoring relies on strategic sensor placement throughout the elevator system. These sensors provide granular data on every aspect of elevator performance.

Essential Sensor Types:

- Motion sensors: Track acceleration, deceleration, and travel smoothness

- Temperature sensors: Monitor motor, brake, and control room conditions

- Vibration sensors: Detect bearing wear, alignment issues, and mechanical stress

- Load sensors: Measure car weight distribution and usage patterns

- Door sensors: Monitor opening/closing cycles and obstruction detection

Data Collection Benefits:

Smart sensors create a complete picture of elevator health, enabling maintenance teams to address minor issues before they escalate. This comprehensive monitoring approach reduces major repair costs by 40-50%.

Implementation Strategy:

Start with critical sensors on high-traffic elevators, then expand coverage based on usage patterns and risk assessment. Prioritize sensors that monitor the most failure-prone components: doors, motors, and control systems.

4. 3D Multi-Beam Door Safety and Monitoring Systems

Door-related issues account for 60% of elevator service calls in commercial buildings. Advanced 3D multi-beam sensors address this challenge while providing valuable monitoring data.

Technology Advantages:

- Earlier movement detection reduces false stops

- Better performance in high-traffic environments

- Reduced wear on door mechanisms

- Enhanced passenger safety and comfort

- Detailed usage analytics for traffic optimization

Ideal Applications:

- Shopping malls and retail centers

- Airports and transportation hubs

- Hospitals and healthcare facilities

- Office buildings with heavy foot traffic

- Hotels and hospitality venues

Performance Impact:

Buildings using 3D multi-beam sensors report 45% fewer door-related service calls and 20% improvement in passenger wait times during peak periods.

Cost Considerations:

While initial investment is higher than traditional sensors, the reduction in service calls and improved passenger experience typically yields ROI within 2-3 years.

5. IoT-Enabled Building Integration Platforms

Internet of Things (IoT) technology connects elevator monitoring to broader building management systems, creating unified facility oversight.

Integration Capabilities:

- Real-time dashboard updates for building operations teams

- Automated reporting for compliance and maintenance records

- Integration with access control and security systems

- Energy usage monitoring and optimization

- Tenant notification systems for planned maintenance

Operational Benefits:

IoT platforms enable property managers to monitor elevator performance alongside HVAC, lighting, and security systems from a single interface. This integration improves response coordination and reduces operational complexity.

Key Features:

- Mobile app access for remote monitoring

- Automated maintenance scheduling

- Vendor management and service coordination

- Compliance documentation and reporting

- Energy efficiency tracking and optimization

Maximizing Your Monitoring Investment

Start with High-Impact Areas:

Focus initial monitoring investments on elevators with the highest traffic or most critical to building operations. This approach maximizes immediate benefits while building experience with the technology.

Plan for Integration:

Choose monitoring tools that integrate with existing building systems and can scale as your portfolio grows. Avoid vendor lock-in by selecting platforms with open APIs and industry-standard protocols.

Staff Training Requirements:

Ensure your maintenance team receives proper training on monitoring platforms. Most property managers see optimal results when at least two team members are fully trained on each system.

Performance Metrics to Track:

- Average downtime per elevator per month

- Preventive vs. reactive maintenance ratio

- Tenant satisfaction scores

- Energy consumption per elevator

- Total cost of ownership including monitoring systems

Implementation Timeline and ROI Expectations

Most comprehensive monitoring implementations take 3-6 months from planning to full operation. Property managers typically see measurable improvements within 90 days, with full ROI within 18-24 months.

Phase 1 (Months 1-2): System selection, vendor negotiations, and installation planning

Phase 2 (Months 2-4): Hardware installation and system integration

Phase 3 (Months 4-6): Staff training and process optimization

The combination of reduced downtime, lower maintenance costs, and improved tenant satisfaction creates compelling business value that justifies the investment in monitoring technology.

For commercial properties seeking to implement comprehensive elevator monitoring solutions, professional guidance ensures optimal system selection and integration. The right monitoring strategy transforms elevator management from reactive maintenance to proactive optimization, delivering measurable improvements in performance, cost control, and tenant satisfaction.

Modern elevator monitoring isn’t just about preventing breakdowns; it’s about optimizing building operations and creating superior tenant experiences through reliable, efficient vertical transportation systems.

Ready to reduce downtime and improve tenant satisfaction? Contact Aspire Elevator Co. for expert monitoring solutions or to schedule a consultation.