Whether you manage a commercial high-rise in Atlanta or own a private residence with a home elevator in Jacksonville, routine safety inspections are non-negotiable. They protect your tenants, your family, and your investment.

But here’s the reality: most elevator problems don’t appear out of nowhere. They develop over time: and they’re often preventable with the right maintenance approach.

In this guide, we’ll walk through the seven most common issues uncovered during elevator safety inspections across Florida, Georgia, and South Carolina. More importantly, we’ll show you exactly how to prevent them before they become costly repairs or compliance violations.

Why Elevator Safety Inspections Matter

Elevator inspections aren’t just a regulatory checkbox. They’re your first line of defense against equipment failures, liability issues, and unexpected downtime. For property managers, a failed inspection can mean taking an elevator offline: disrupting tenants and operations. For homeowners, it can mean safety risks for your family and guests.

The good news? Most inspection failures stem from a handful of recurring issues. Address these proactively, and you’ll stay ahead of problems instead of reacting to them.

Issue #1: Failed Emergency Car Lighting

What inspectors find: Emergency lighting systems inside the elevator cab fail to activate during power outages. This happens because backup batteries degrade over time and aren’t replaced on schedule.

Why it matters: If your elevator loses power and the emergency lights don’t work, passengers are stranded in complete darkness. Beyond the safety hazard, failed emergency systems are an immediate inspection failure in most jurisdictions.

How to prevent it:

- Replace emergency lighting batteries at manufacturer-recommended intervals (typically every 1–3 years)

- Include emergency lighting tests in your quarterly inspection checklist

- Document all battery replacements in your maintenance log

Issue #2: Inadequate Machine Room Lighting

What inspectors find: Machine rooms and elevator pits lack sufficient lighting, or existing lights aren’t accessible from the room entrance. This creates hazards for technicians performing maintenance.

Why it matters: Poor lighting in mechanical spaces leads to accidents, missed maintenance issues, and code violations. Inspectors check that lighting meets specific lumen requirements and is easily accessible.

How to prevent it:

- Schedule monthly visual inspections of machine room lighting

- Verify that light switches are located at room entrances

- Replace burned-out bulbs immediately: don’t wait for inspection day

Issue #3: Malfunctioning Door Restrictors

What inspectors find: Door restrictors: the safety devices that prevent elevator doors from opening when the cab isn’t at a landing: fail to operate correctly. This is one of the most serious safety violations an inspector can identify.

Why it matters: A malfunctioning door restrictor can allow doors to open into an empty shaft. In many states, elevators with failed door restrictors must be immediately removed from service until repairs are completed.

How to prevent it:

- Test door restrictors monthly as part of routine maintenance

- Monitor for any hesitation, unusual sounds, or alignment issues

- Schedule professional inspections if you notice any irregularities

Issue #4: Door System Problems

What inspectors find: Elevator doors that don’t open or close smoothly, get stuck, or reverse inconsistently. These issues typically stem from misaligned sensors, dirty door tracks, or worn mechanical components.

Why it matters: Door problems are among the most frequently reported elevator issues. They frustrate users, slow building traffic, and often indicate deeper mechanical concerns that will worsen over time.

How to prevent it:

- Clean door tracks thoroughly and regularly

- Calibrate door sensors according to manufacturer specifications

- Address any jerking, hesitation, or unusual door behavior immediately

- Schedule professional sensor recalibration at least annually

Issue #5: Unusual Noises and Vibrations

What inspectors find: Grinding, rattling, squeaking, or thumping sounds during elevator operation. These noises often indicate misaligned components, loose parts, or insufficient lubrication.

Why it matters: Unusual sounds aren’t just annoying: they’re early warning signs. Left unaddressed, minor mechanical issues can escalate into major repairs or sudden breakdowns. Inspectors note these conditions and may require follow-up maintenance.

How to prevent it:

- Train building staff to report unusual elevator sounds immediately

- Include listening checks in monthly visual inspections

- Maintain proper lubrication schedules for all moving components

- Don’t ignore small noises: investigate them promptly

Issue #6: Erratic Movement and Power Failures

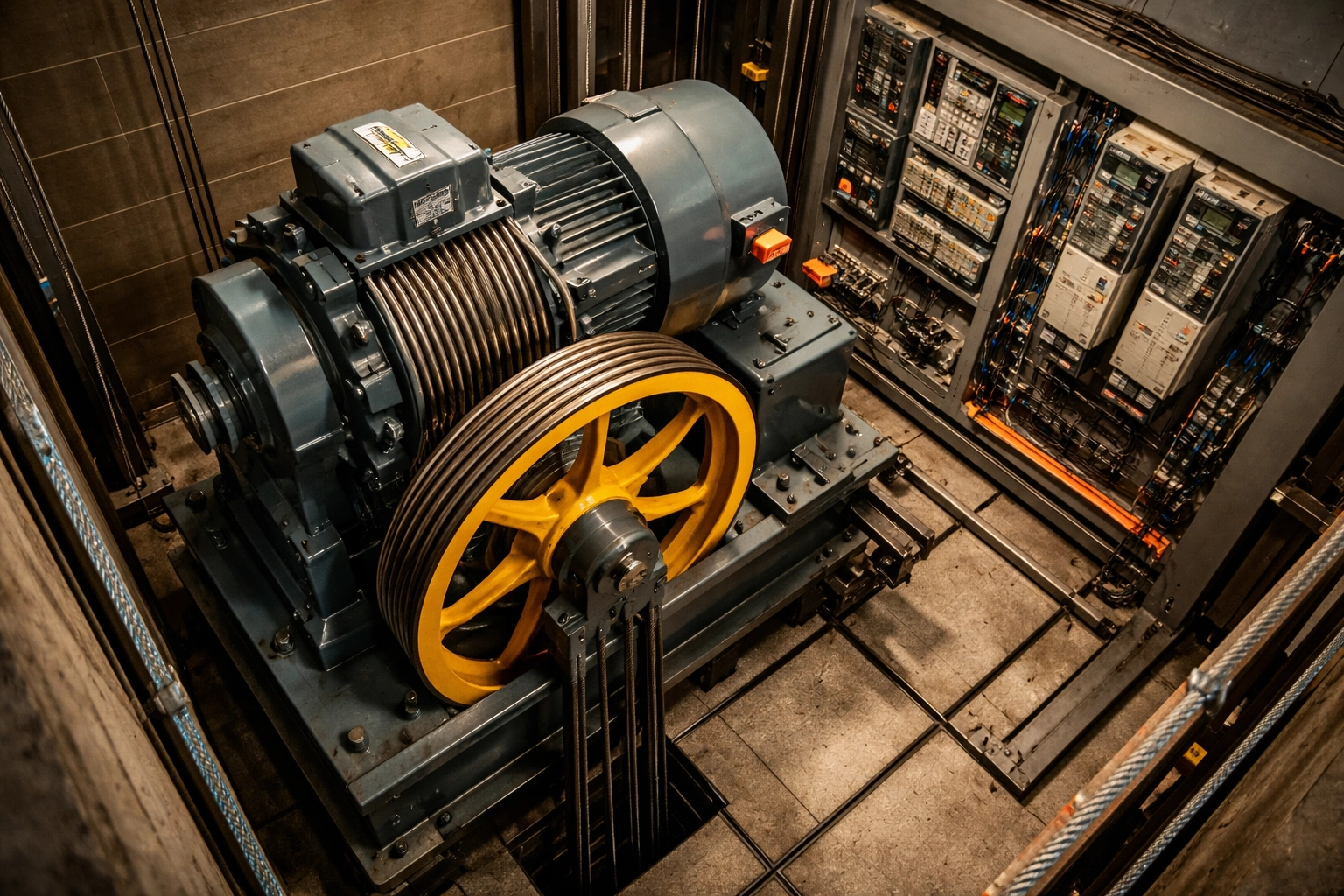

What inspectors find: Elevators that stop unexpectedly, move erratically between floors, or fail to respond to controls. These problems often involve control system malfunctions, electrical issues, or mechanical failures in pulleys, counterweights, or braking systems.

Why it matters: Erratic elevator behavior creates immediate safety concerns and significant liability exposure. Power failures can strand passengers and disrupt building operations for hours.

How to prevent it:

- Conduct quarterly comprehensive inspections that include:

- Testing all safety systems

- Checking cable tension

- Inspecting motor and drive components

- Evaluating electrical connections

- Verify backup power systems (generators, battery backups) are functional

- Keep detailed maintenance logs to identify patterns before failures occur

Issue #7: Overheating Components

What inspectors find: Motors, cables, bearings, or control systems running at elevated temperatures. Overheating is especially common during high-usage periods in commercial buildings.

Why it matters: Overheating components can trigger system shutdowns, accelerate wear, and in extreme cases, create fire hazards. This issue often goes unnoticed until it causes a breakdown.

How to prevent it:

- Ensure machine rooms have adequate ventilation

- Maintain proper lubrication levels on all bearings and moving parts

- Consider thermal imaging inspections to detect hot spots before they cause problems

- Replace worn components promptly: don’t push equipment past its service life

Building Your Prevention Strategy

Preventing these seven issues comes down to three fundamentals:

1. Establish a consistent maintenance schedule

- Monthly visual inspections for obvious issues (lighting, sounds, door operation)

- Quarterly comprehensive inspections covering all mechanical and electrical systems

- Annual professional assessments with certified technicians

2. Document everything

Maintain a detailed maintenance log that tracks inspections, repairs, and component replacements. This documentation helps you predict when parts need attention and demonstrates compliance during inspections.

3. Work with certified professionals

Elevator systems are complex. Attempting DIY repairs or inspections can disable critical safety functions and create liability. Partner with experienced, certified elevator professionals who understand state and local codes in Florida, Georgia, and South Carolina.

The Bottom Line

Elevator safety inspections don’t have to be stressful. When you understand the most common issues: and take proactive steps to prevent them: you’ll pass inspections with confidence, avoid costly emergency repairs, and keep your elevators running safely for years to come.

The key is consistent, professional maintenance from a team that knows your equipment and your local requirements.

Ready to Schedule Your Inspection?

At Aspire Elevator Co., we provide comprehensive elevator inspection, maintenance, and repair services for commercial properties and residential elevators throughout Florida, Georgia, and South Carolina. Our certified technicians deliver transparent pricing, no hidden fees, and responsive service you can count on.

Whether you need a routine inspection, preventive maintenance program, or help addressing a specific issue, we’re here to help.

Call us today to schedule your elevator safety inspection or discuss a maintenance plan tailored to your property.

Leave a Reply